Case Studies

RM Headlee & Zwick Handles The Heat

A Northeastern Natural Gas fired electric producing power plant (operating at temps that reached 900 degrees – that’s toasty!) required a valve package with absolutely zero leakage. We answered the call!

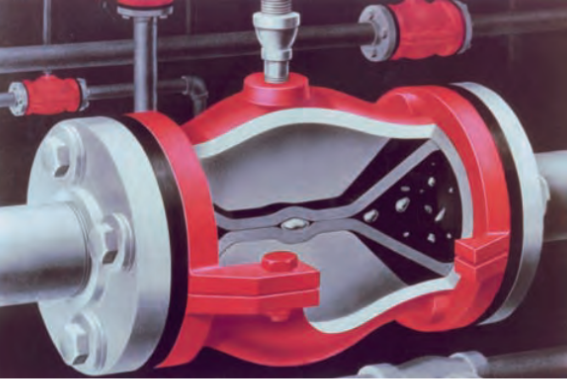

Red Valve Pinch Valve Restores the Fountain at Cobbs Hill Reservoir

The gate valve and hydraulic system in the fountain of Rochester, NY’s Cobbs Hill Reservoir served a long service life of over 100 years. When it became inoperable, the city searched for options to keep the fountain in service. RM Headlee answered the call.

AUMA Actuators for Natural Gas Service

AUMA Actuators, Inc. (AUMA–USA) and R.M. Headlee won a job with the largest energy infrastructure company in North America.

This customer operates 152 terminals as well as 85,000 miles of pipelines, which transport natural gas, gasoline, crude oil and carbon dioxide.

Case Study AUMA Natural Gas Service

SMARTSTEP 100% Duty Servo Electric Actuator

RM Headlee, a New York based distributor of valves, actuators and controls developed a simple control package for the water markets. Many municipalities have older equipment controlling their filter beds. Most of the valves, actuators and liquid level components are no longer made with no supporting spare parts. There are three primary items needed to upgrade to a simple, accurate proven system.

Case Study SmartStep For Liquid Level Control

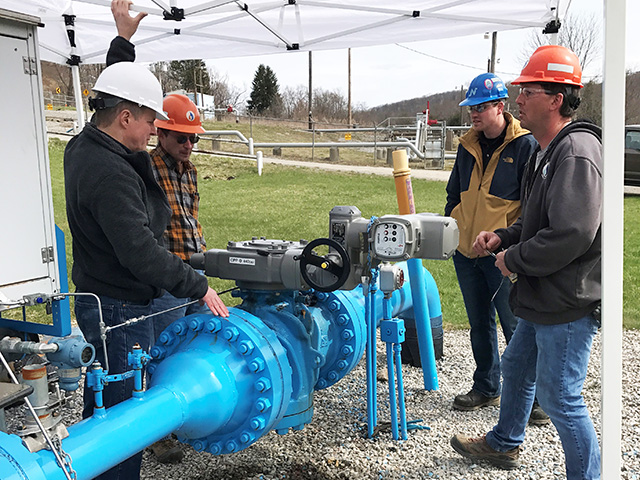

Val-Matic Chosen for Largest Tank East of Rocky Mountains

The City of Syracuse’s largest capital investment in water infrastructure included the Val-Matic American butterfly valve for the Westcott Reservoir Rehabilitation Project. Two new 32 MG concrete tanks, largest east of the Rockies, will replace the 110 MG concrete lined reservoir that was taken out of service in 1999.

Steel Mill Outage

An up-state New York steel mill needed to replace a leaking 24” pneumatically operated butterfly valve.

This steel mill selected R.M. Headlee Co., Inc. as the supplier due to their valve expertise and ability to meet the tight time schedule due to the upcoming maintenance outage.

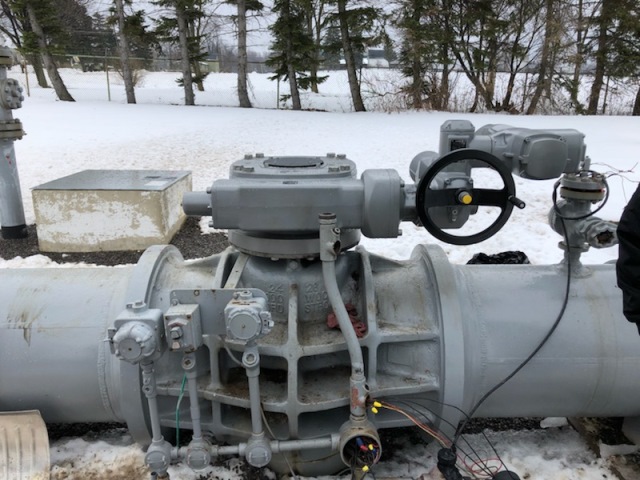

AUMA Wins Natural Gas Retrofit Opportunity

AUMA Actuators, Inc. and R.M. Headlee secured an opportunity to install AUMA actuators with a natural gas company in western Pennsylvania.R.M. Headlee retrofitted a SAREx 10.2/GS 160.3 with AMExC 01.1 integral controls on a 12″ AN-SI 300 Audco Plug Valve. The retrofit was completed in the field, which lessened the amount of time production was suspended.

Case Study AUMA in Natural Gas Service

A-T Selected for its Custom Design & Flexibility

When our client needed new equipment to assimilate space conditions they turned to the expertise of R.M. Headlee Valves & Controls and the proven performance of A-T ball valves.

The requirement was to test a multitude of gases under full vacuum and extremely high flows in an aerospace wind tunnel utilizing automated ball valves.

Case Study AT For Areospace Technology

Edinboro Lake Dam

New Orbinox stainless steel sluice gate and stop log at Edinboro Lake dam will help control lake water levels. Edinboro Borough Manager T.J. Jemetz said, The new gates will allow for increased water flow from the dam into Conneauttee Creek when necessary.

Amherst Coarse Bubble Aeration System

Providing optimal oxygen transfer and mixing characteristics with reliable backflow prevention, Tideflex Aeration and Mixing Systems are ideal for use in municipal and industrial aeration applications.

Case Study Tideflex Coarse Bubble Aeration

R.M. Headlee Valve Automation Center

The RM Headlee Valve Automation Center was able to retrofit the (7) year old electric actuators onto the new valves and perform the AWWA pressure test. AWWA requires each valve be pressure tested after the actuator has been installed on the valve and limit switches and travel stops have been set to insure trouble free performance.

Case Study Valve Automation Center

Electric Actuators with Remote Mounted Controls

One of the largest Natural Gas Transmission Utilities in North America awarded R.M. Headlee Co., Inc. with two orders for AUMA electric valve actuators. These explosion proof actuators are installed at a transmission compressor station on ANSI Class 600 suction, discharge and by-pass API-6D trunnion ball valves and plug valves.

Case Study Electric Actuators with Remote Controls

Field Retrofit AUMA Electric to 16″ ANSI 1500 Plug Valve

This AUMA Electric Valve Actuator was mounted to a 16″ ANSI 1500# plug valve at a large Natural Gas Utility in Eastern, USA. The challenge on this project was taking off a very old competitors actuator that was firmly rusted to the valve stem and bracket. Due to the required valve torque this actuator needed 250,000 ” lbs for modulation flow control using 4-20mA with 4-20mA feedback. This Explosion Proof model meets all “FM” Class-I, Div-I certifications and IP68-8-D weather protection enclosure to avoid water ingress that would freeze inside the unit.

Case Study AUMA to 16″ ANSI 1500 Plug Valve

Contact Us Today!

No two process applications are alike, which is why our technical experts collaborate with you to provide the right technology to deliver reliable results for your site’s unique challenges.