Tideflex

Maintenance-free Backflow Prevention

Tideflex, a division of Red Valve, has become the world standard for maintenance-free backflow prevention featuring:

- CheckMate UltraFlex Inline Check Valves

- Tideflex Check Valves

- Tideflex Aeration & Mixing Systems

- Tideflex Hydraulic Recirculation & Mixing Systems

- Tideflex Potable Water Mixing Systems

Tideflex was created in 1984. As a result, the elastomer duckbill Tideflex®️ Check Valve was specifically designed to eliminate operation and maintenance problems associated with flapgate valves – including corrosion, freezing open or shut, warping and clogging.

The EPA tested the Tideflex®️ Check Valve for two years and found that it showed significant improvement over flapgate valves in terms of leakage inflow, debris entrapment, self-cleaning and marine fouling. Today, hundreds of thousands of Tideflex®️ Check Valves are installed and performing reliably worldwide. Tideflex®️ Check Valves have become the world standard for maintenance-free backflow prevention.

Today, RM Headlee has provided several thousand Tideflex Check Valves, Dozens of Tideflex Aeration and Mixing Systems, and has installed over two hundred Tideflex Potable Water Mixing Systems in Upstate New York.

If you need a simple proven valve or mixing system for difficult applications look no further than Red Valve – Tideflex and RM Headlee.

CheckMate UltraFlex

A Revolutionary Design for Backflow Prevention

The CheckMate® UltraFlex™ is the most user friendly inline check valve on the market today. From the upstream or downstream end of the pipe, simply insert the valve into position and clamp it into place. Typically no modification to the pipe or structure is required.

Tideflex CheckMate Inline Valve Operation Animation

Tideflex Check Valves

Tideflex Duckbill Check Valves have low headloss and achieve the tightest possible seal for backflow operations, particularly at low flow rates. The flexibility of the Tideflex Check Valve allows the valve to compress around trapped solids, providing a much better seal than flapgates. With the development of the patented Curved Bill, sealing capabilities are further improved because the Curved Bill is more flexible than the rest of the valve and will compress even more around solids.

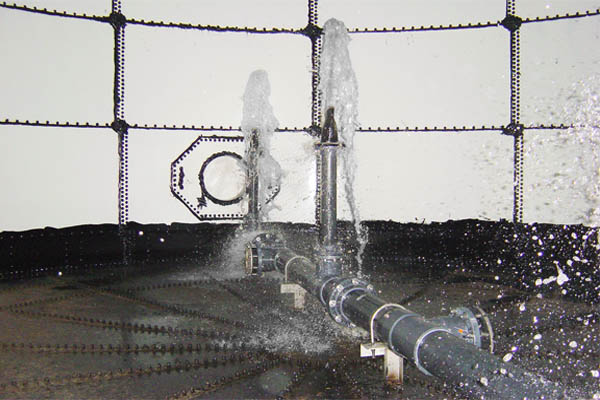

Tideflex Mixing Systems (TMS) For Potable Water Storage Tanks

Custom Engineered for an Innovative Mixing Solution

Tideflex Check Valves are the key player in the Tideflex Mixing System (TMS). Developed in the 1980s from a United States EPA grant, the check valve was created to solve backflow problems in outfall pipes.

Tideflex Engineers further expanded the use of the Tideflex Check Valve by integrating the valve into a Variable Orifice Inlet Nozzle, which provides superior mixing characteristics when compared to a fixed-diameter pipe.

When used in the TMS, the Tideflex Variable Orifice Nozzles optimize jet velocity at all flow rates and discharge an elliptically shaped jet, achieving rapid and complete mixing and improving water quality. The TMS also separates the inlet and outlet with one manifold pipe, eliminating short-circuiting, water stagnation, dead zones and stratification.

Safety Data Sheet (PDF)

New York State Installations

Contact Us Today!

No two process applications are alike, which is why our technical experts collaborate with you to provide the right technology to deliver reliable results for your site’s unique challenges.