Pressure Management

Pressure Control Valves

Controlling or venting pressure in a closed piping or vessel system is critical for safety reasons. Most if not all equipment has a certain pressure rating that never should be exceeded.

Expressed as MAOP (Max allowable operating pressure) or MAWP (working pressure) and is governed by the US guidelines of ASME.

Valves used in PM fall into two general categories: Non-closing devices that vent 100% of all pressure & Self-closing devices that vent/open at a given set point and flow a calculated amount of pressure/volume then close holding the remaining pressure.

Both valve categories come in different sizes with machined orifices having unique flow coefficients which are derived by physical testing from the National Board (NB) in Columbus, OH.

This testing results in certification of actual capacity at a given set point. Actual valve performance varies greatly between all valve manufacturers.

Rupture Disc’s are a non-closing device perfect for fire sizing, when dumping all of the process is allowed or preferred. The holder that clamps the thin sheet of metal (called the disc) can be re-used, the disc must be replaced

Control valves could also be considered PM valves and they can be viewed in our control valve RM Headlee web site section.

Pressure Relief Valves

Pressure Relief Valves are self-closing and better designs can pop many times and remain bubble tight. Ten percent (10%) over-pressure is allowed by ASME. This category includes weight-loaded, conventional spring, pilot operated styles.

R.M. Headlee is a leading supplier of safety relief valves in New York, Northern PA, and Vermont. We carry devices from the major manufacturers below. Contact us for product specifics or an estimate.

Continental Disc

Rupture discs for a variety of process industries

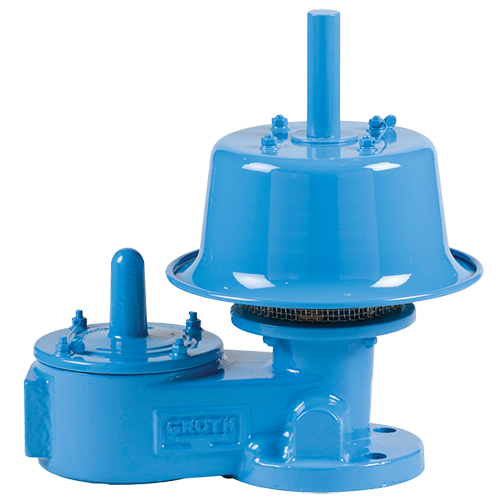

Groth Corp

Pressure/Vacuum Relief Valves, Pressure Relief Valves, Vacuum Relief Valves, Pilot Operated Valves

Contact Us Today!

No two process applications are alike, which is why our technical experts collaborate with you to provide the right technology to deliver reliable results for your site’s unique challenges.