Courses

Valves for Industrial Applications

Many different types of valves are used for industrial applications today. New and innovative products are being introduced to reduce maintenance costs and to simplify plant operations. As new technologies continue to evolve, choosing the valve that offers the best cost of ownership can be confusing.

Valve Actuation

New and innovative products are being introduced to reduce maintenance costs and to simplify plant operations. As new technologies continue to evolve, it is important to choose the actuator that offers the best cost of ownership. Considerations like valve style, ambient conditions, power availability, process control, type of service, safety, location and maintenance to name a few, all must be part of the actuator selection equation. The course will include discussion on multi-turn, quarter-turn and linear actuators.

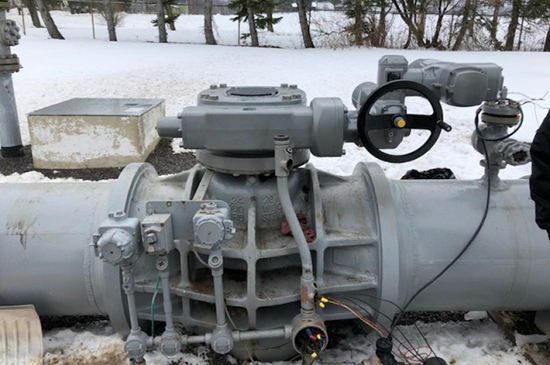

Introduction to Electric Actuators

Electric actuators are used in municipal and industrial applications to actuate all types of valves today. New and innovative products are being introduced to reduce maintenance costs and to simplify plant operations. As new technologies continue to evolve, it is important to choose the actuator that offers the best cost of ownership.

Maintaining Disinfectant Residuals In Water Storage Tanks

Deterioration of water quality in finished water storage facilities is one of the most important issues facing water utilities. The most common problem in reservoirs is the loss of disinfectant residual resulting from hydraulic short-circuiting, poor mixing and circulation, poor turnover, and excessive detention time. Many of these water quality problems can be specifically attributed to the location and orientation of the inlet and outlet pipe(s).

Valves for Municipl Applications

Valves are used to regulate the flow of fluids in piping systems. They are used to throttle flow, shut-off flow, reduce pressure, relieve pressure and prevent backflow. Valves are one of the simplest components in most piping systems, but the importance of proper valve selection cannot be overemphasized. Premature valve failure can result in loss of fluid pressure containment, which often leads to undesirable consequences. As new technologies continue to evolve, choosing the valve that offers the best cost of ownership can be confusing.

Valves for Commercial Applications

New and innovative products are being introduced to reduce maintenance costs and to simplify plant operations. As new technologies continue to evolve, choosing the valve and actuator that offers the best cost of ownership is important. Considerations like safety, valve style, valve standards, media, flow, pressure, seat design, shutoff, control, and maintenance must be part of the valve assembly selection equation.

High Solids Mixing

This presentation will review the current design approach for mixing systems used on high solids concentration, process fluids within wastewater treatment processes. The operational state of fluids can be either aerobic or anoxic and requires the mixing systems to maintain these environments. Methods of ‘old school’ mixing design approach will be evaluated against today’s operational methods of wastewater treatment. Designing systems that have low maintenance demand in highly aggressive process fluids is key to the longevity of the system operation.

Contact Us Today!

No two process applications are alike, which is why our technical experts collaborate with you to provide the right technology to deliver reliable results for your site’s unique challenges.