R.M. Headlee Restores Working Condition To the Fountain at Cobbs Hill Reservoir, Rochester, NY

The Client: The City of Rochester, NY

The Challenge: Sizing Control Valve for the Fountain

The requirements were:

• Vendor needed to size valve to create the required backpressure during summer and

winter months

• The solution required the valve and actuator to be capable of total submergence.

• Valve actuator needed to be throttled from the gate house

And of course, this solution needed to be cost effective, and implemented quickly.

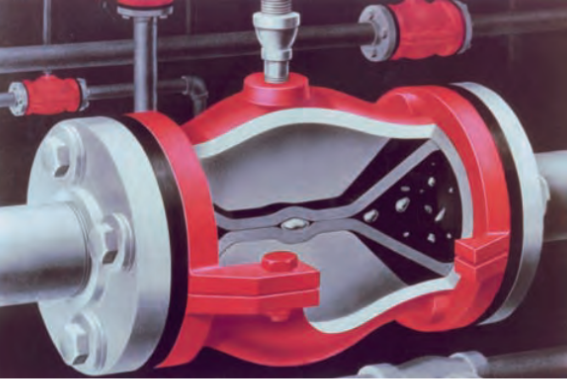

The Solution: A Red Valve® Pinch Valve with 24″ x 20″ Cone Sleeve

Actuation of the Type A, the PINCHING action, is accomplished by air or hydraulic pressure placed on the elastomeric sleeve. The valve body acts as a built-in actuator, eliminating costly and hard to submerge pneumatic, hydraulic or electric actuators.

Modulating the air/hydraulic pressure within the annular space between the body and sleeve will open, throttle or close the valve. RM Headlee proposed using city water, that was readily available, to actuate the valve.

The Result: On-Time Project Completion with Long Term Maintenance Flexibility

R.M. Headlee’s solution was accepted, installed and to this day still proving the spectacular view of the 115 year old fountain that is enjoyed by hundreds of daily walkers, bikers and joggers!

About Red Valve

Established in 1953 and having over 57 patents, Red Valve is a manufacturer and leader in valve flow technology and mixing systems. Red Valve is based out of Pittsburgh, PA and now boasts a newly upgraded North Carolina production factory.

Starting out in the mining industry, Red Valve solved valve issues using an elastomeric pinch design and worked to create improved products including flexible duck-bill check valves. These check valves open in proportion to system flow and pressure and won’t ingress contaminants when the system is not running. Mixing water in storage tanks using the pump pressure is an advantage compared to competitors who must bring in electrical power. Learn more about RM Headlee’s suite of Red Valve products here.

Contact Us Today!

No two process applications are alike, which is why our technical experts collaborate with you to provide the right technology to deliver reliable results for your site’s unique challenges.