“Heads Up”

Quarterly Newsletter: October, 2023

Jump To

Latest News | Application Guidelines | Technically Speaking | Final Comments

Latest News

“Time”

Holy FALL Ghost Rider, where did the summer go? I don’t know about you, but to me, it seems TIME goes by faster and quicker than ever before. Speaking of TIME, I have a few comments to share!

If you are a client, supplier, contractor, or consultant there are many actions you can take to save TIME. Certainly, working long hours and being organized are right up there on the list, but let’s examine a few more:

- Know and understand what you’re talking about. Clients favor those calling on them who have deep product knowledge and history of the equipment they sell and support.

- Don’t waste TIME. When across the desk from a customer get to the point. Unless you’re asked, leave the little league baseball score of your sonny boy out of the meeting.

- Be prepared. If you’re asked to put on a control valve sizing seminar for 25 people, don’t spend the first half of the meeting talking about $20.00 floating ball valves. Show up early, presentation well-rehearsed, with fresh sandwiches, listen sharply to the questions and answer them efficiently and accurately. Do not gravitate to the Buffalo Bills.

- Have clear specs. Write specs that are technically achievable and satisfy the end user’s need. Using a single source is never good, unless the product is carried by RM Headlee, just kidding.

- Follow through and respond back quickly. Included with your answer should be supporting details of your answer, 3D drawings if requested, spec sheets that are concise and an easy-to-read proposal with options.

Hollywood actor Denzel Washington was in a well-known movie called “ Man on Fire.” In one scene he mentions: “I wish you had more TIME.”

Enjoy your TIME soon seeing the leaves change color, apple cider, carving pumpkins and all other fun things that come along this TIME of year!

Application Guidelines

The natural gas industry uses many valves of different types. They primarily fall into two categories:

- Blocked flow and pressure with the valve position being either fully open or closed

- Control of the flow and pressure with valve position being modulated throughout the open and closed stroke

The challenge is achieving zero seat leakage in the closed position for both categories. Different valves have different applications — check out the breakdown below:

Plug valves with metal-to-metal internals operate well for blocked flow and controlled flow applications, but depend on grease for positive shut-off and have a high pressure drop due to the internal plug restriction.

Ball valves using elastomeric seats can be damaged from line dirt causing leakage, but they excel in flow restriction because they are full port and have zero pressure drop. However, ball valves can not be used for modulation control. Certain double-seat ball valve seat designs have shown promise in high-pressure vents with high differential pressures and are replacing plug valves.

Axial Flow valves use a coned internal plug that moves laterally inside the valve body to achieve both control and blocked position with zero leakage, but only in ultra-clean fluids. If your pipeline has any particulate at all, even small micron size, you will not get positive shutoff.

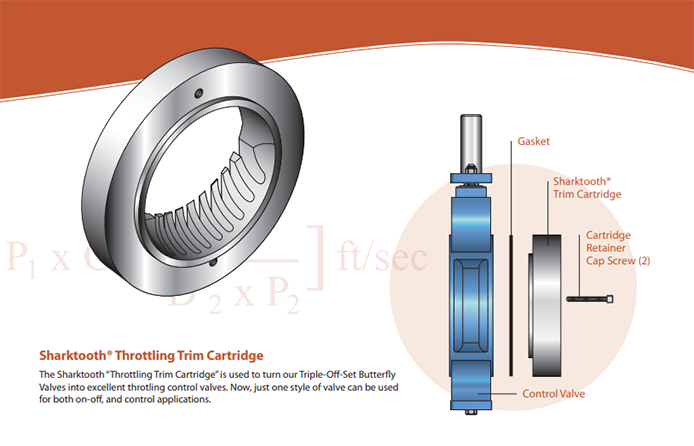

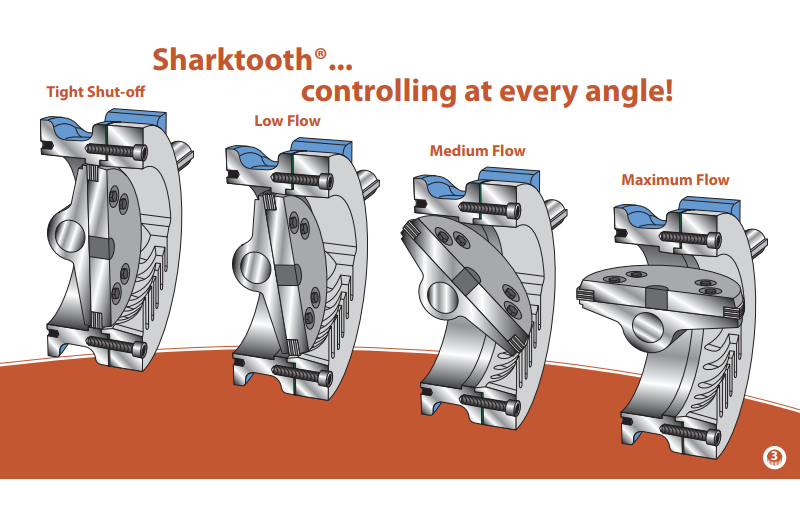

There is a fourth style valve showing recent promise and that is the Triple Offset (TOS) metal to metal, zero leakage butterfly valve. Designed with three offsets, plus a keyed (others use a pinned permanent assembly) disc to stem self-centering attachment, allows these valves not to rub into the seat or pop out of the seat. This design makes the Triple Offset valve an excellent option for block and control applications.

For control applications, a S/S element (shark-tooth) with machined curved fingers is attached to the TOS body, providing true, equal percent control at better than 100:1+ reduced cavitation. The best part is TOS valves provide zero leakage seats, so you get top performance control and complete shut-off capabilities which are not available with globe-style control valves.

TOS valves, Ball valves and Plug valves are 90 degree or quarter-turn style valves, while Axial valves are linear up and down stem drive valves. All can be actuated with pneumatic, electric or gas-hydraulic actuation.

Contact R.M. Headlee for the best valve option in natural gas applications.

Technically Speaking

Sliding Gate Valves by Schubert & Salzer

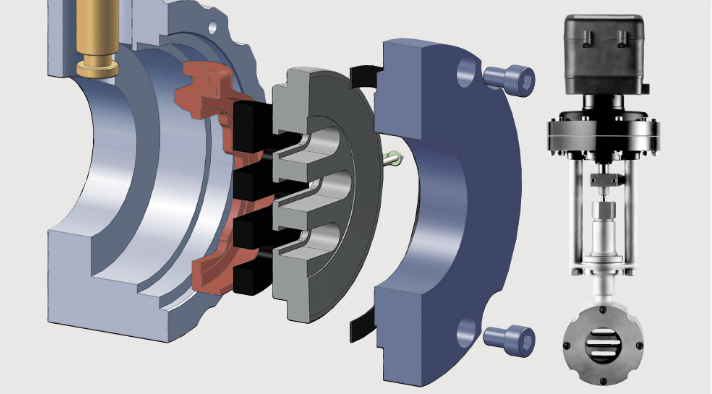

Over 40 years ago, Schubert & Salzer’s Sliding Gate products were developed as an efficient alternative to conventional control valves. The GS series incorporates a unique, variable orifice principle which translates into a highly efficient, yet simple design.

The GS Valve controls a variety of media, including steam, liquids and gases. A fixed plate or disc is set into a wafer-style body with a variety of orifices machined into the material. These slots can vary in design, size and configuration which determine the flow coefficient (Cv) and the flow characteristic. A moving disc of similar size and design also has a series of orifices, but only one type which represents the highest flow capacity of the particular line size.

This disc moves against the plate, creating a straight-through flow path for the process media. As the valve modulates flow is broken apart; it creates a variable field of area flow which reduces energy and noise. The differential pressure creates a unique seal between the two plates and when in the sealed position, an overlap of approximately 1 mm creates a leak-tight valve.

The Sliding Gate Valve will provide the precision you expect at a fraction of the size, weight and cost of conventional control valves.

Final Comments

I have family that work in the Pharma Sales industry and although selling industrial process equipment is much different than pills, devices or vaccines, it still is selling a product to a client. All of us suppliers hone our skills to deeply understand, and then convey, the benefits of our products, hoping to gain interest from engineers or doctors. We follow industry guidelines and rules of ethics, pricing and warranty, representing details of what the product delivers to the end-user or consumer in an accurate fashion.

Sales is not for the weak of heart as we travel great distances, have long days often requiring hotel overnights and many times, are only allowed just a few minutes to see the client or decision maker. There are also times when the person whom we confirmed the meeting with either can’t or won’t attend a meeting, sending, usually, non-decision makers in his or her place. This can be both frustrating and make those who are thin-skinned question if they chose the right career.

The good news is, this is the exception and not the rule. Plus, both sides understand unavoidable circumstances happen from time to time and you work through it. I like to think those of us in sales are the tip of the spear as we are thrown forward with new information and ideas vetted by scientists or design engineers, looking for our mark.

My message is only this: both suppliers and clients are professionally trained, educated people equally wanting to make all of us aware of state-of-the-art and safe products that truly help.

Finally, this may be my last newsletter as I’m retiring October 31, 2023. I intend to remain on as needed with the RM Headlee Team as a consultant or for special projects. I’ve been working since college for over 45 years and it’s time to pass the torch, spoil my three grandkids and go on a few trips with my high school sweetheart whom I’ve been married to since 1981. I’ve had a great ride, met many wonderful people and traveled the world selling. Remember, nothing happens until somebody sells something!

Gary Beckett, Vice President of Business Development

Recent Comments