“Heads Up”

Quarterly Newsletter: June, 2023

Jump To

Latest News | Application Guidelines | Technically Speaking | Final Comments

Latest News

Service, Service, Service!

Anyone can sell a valve, actuator, control system or piece of equipment. But… can everyone who sells those products or services support what they sold? I think not.

Certainly, a salesperson must know a little about what they are selling. But, those that dive deep to understand design, performance, application, comparison to competition, and above all those, will visit the installation site are, in my mind, the most important suppliers to work with.

The well-used phrase “Service with a Smile” can be observed at many company headquarters board rooms or lobbies. It’s no coincidence that many of those companies have been in business for many, many years. Why? Because competent technical service is important. R.M. Headlee believes in service before, during and after the sale. Heck, we will even come out and service competitors’ equipment if problems arise, because we know equipment in the field that goes down can be expensive and sometimes dangerous to client operations.

We prefer to work on what we sold, but if we get any piece of equipment back up and running, many times we win over a client and on the next project our product lines are purchased, and not the competition.

R.M. Headlee has sent most of their employees to training schools and sales meetings held by the manufacturers we represent. Even though this is expensive and time consuming, our goal is to arm our staff with the tools and skill set to help us be the best we can be for our customers.

R.M. Headlee also carefully chooses the manufacturers (MFG) we present. Much effort goes into vetting MFG history, customer service, fairness on disputes, quality control and cost of goods. We also attend most – if not all – Water, Wastewater & Natural Gas conferences, helping us stay current with the markets and clients we make a living with.

As we approach the summer and the mid year for this fast-moving 2023, we hope you and yours are healthy with good fortune.

– Gary Beckett, V.P. of Sales

Application Guidelines

Almost four years ago, our Therese Constable answered a phone call that came into the RM Headlee Sales Dept. When she passed the call over to me, using her incredible sense of humor, she said, “Gary, XYZ Company is on line four. Try not to blow it.” That initial phone call lasted over 20 minutes and culminated in dozens of meetings, site location visits, and valve design reviews over the course of four months.

Note: This client asked that an NDA be part of this process so the end user or specific application would be withheld for this publication.

The application required a butterfly valve and pneumatic actuator having zero leakage when fully closed. It needs to be operable at temperatures approaching almost 900℉ with a valve size 48 inches. Those with industrial valve skill sets know immediately that soft seated valves were out the window. Only metal seated valves had a chance of working well and lasting.

When offering the customer a choice between Double Offset High-Performance butterfly valves or Triple Offset Butterfly Valves, the preference ended up being Triple Offset due to the criticalness of absolute zero leakage when fully closed. R.M. Headlee’s go-to Triple Offset is Zwick, manufactured out of Germany. However, there is a U.S. Zwick facility located out of Deer Park, TX just south of Houston.

The Zwick valve design is manufactured with a self-centering disc that is keyed to the shaft, not pinned, to assure a perfect seat engagement into the machined body. This design feature reduces disc jamming and popping out of the seat when thermal expansion conditions exist.

Technically Speaking

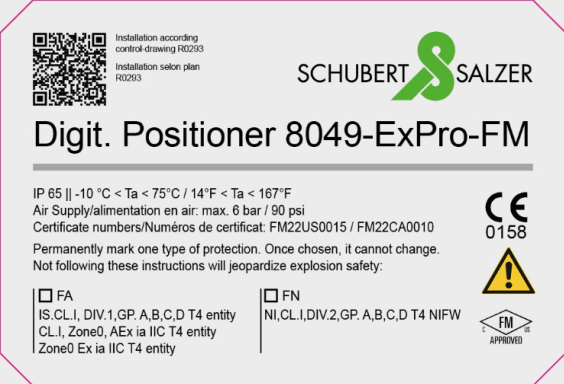

Schubert & Salzer have announced the new Explosion Proof Certification, Type “FM” on their 8049 Digital Positioner.

The digital positioner 8049-ExPro with ATEX and IEC type examination certificates are ideal for applications in hazardous areas and have been successfully certified by FM Approvals LLC (Certificate no. FM22US0015 for the USA and Certificate No. FM22CA0010 for Canada). For corresponding requirements, especially from the North American markets, we can now supply individual Ex Positioners (8049-ExPro-FM) or valves with integrated Ex Positioner and FM certificates for Zone 0, Class I, Division 1 or 2 applications.

The Digital Positioner type 8049 ExPro-FM is always designed with a stainless steel base plate and with electrical, as well as pneumatic connection in NPT.

Final Comments

The Great Lakes combined reflect 21% of the earth’s freshwater, covering an area of 94,250 sq miles and the 2nd largest by total water volume to a single lake north of Mongolia in Russia. R.M. Headlee (RMH), located in western New York, is close to being right in the middle of these five lakes. RMH, with over 53 years in business, is strong in the water markets.

Many of our product lines focus exclusively onto these markets that involve every aspect of water, whether it be Engineering Consultants, Mechanical Contractors or Municipalities. Our goal is to provide valves, actuators and controls that meet New York State and US Federal codes and specifications with safety at the best value.

Projects funded with Federal dollars many times require AIS (American Iron & Steel Act) compliance, assuring a certain percentage of monterary equipment cost are made with material sourced from the US. These five lakes are a magnificient natural resource and we prioritize choosing equipment that provides safe, potable drinking water that is properly cleaned so it can be returned back into our waterway.

R.M. Headlee has the valve, actuator and control products for all your water needs. Contact us today to learn more about our product lines.

Gary Beckett, Vice President of Business Development