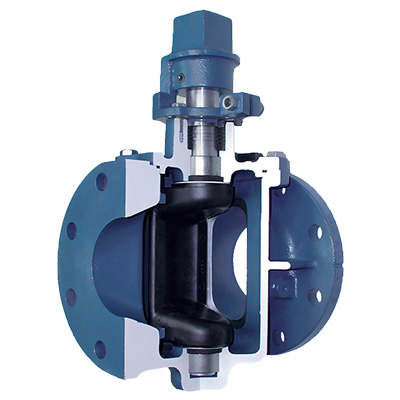

Plug Valves

Plug valves typically fall into two design categories: Lubricated and Non-Lubricated. Lubricated styles require a viscous grease or thick paste hydraulically injected into the small machined clearance around the plug and it’s this grease that helps the valve seal off the process media when the valve is in the closed position.

Lubricated vs. Non-Lubricated

Lubricated plug valves usually have all-metal internals making this style last longer in dirty service, modulation for control, or higher velocities. This style is used commonly in the Natural Gas Industry.

Non-Lubricated styles don’t use grease for sealing. This design typically clads or vulcanizes an elastomer onto the plug or body (Buna, Viton, EPDM, other) to achieve close to zero leakage when in the closed position. Non-Lubricated plug valves are used often in applications of water & wastewater.

Plug valves can also be internally lined with corrosion-resistant materials such as Teflon or KihNare to help lower cost when compared to high alloy metal materials such as Inconel, Hastelloy, Monel, or others. Lined plug valves can be found throughout the chemical industry.

Features of Plug Valves

- Abrasive resistant

- Block or throttling

- 90-degree cycle

- Dirty service

Common Applications

- Natural gas industry

- Water and wastewater

- Chemical Industry

Contact Us Today!

No two process applications are alike, which is why our technical experts collaborate with you to provide the right technology to deliver reliable results for your site’s unique challenges.