“Heads Up”

Quarterly Newsletter: December 2021

A quarterly newsletter from R.M. Headlee for the purpose of customer and principal communications, sharing best application methods, product features and benefits and doing what it takes to achieve complete customer satisfaction.

I cannot believe it has been since June of 2019 since our last RM Headlee Newsletter. The Covid-19 pandemic has had so many far reaching effects on all of us. Working from home had its up and downs.

I would ask my wife of 41 years as she approached me in our dining room/ remote office, if she had an appointment as it was easy for her to stop by for a chat. After all, I was trying to work. This approach did not work out well for me.

Gary Beckett, VP Business Development

New Product Lines

RM Headlee has picked up a few new product lines as we continue to grow and remain busy.

- RODNEY-HUNT has joined our product mix and we are very excited to represent their second to none extensive line of Gates. R-H is a world best in class manufacturer with over 100 years of experience.

SCHUBERT & SALZER although not new with us has just announced a new valve design, there series 8621. This control valve using sliding gate technology now incorporates standard API face to face flange connections ( ASME B16.34 & B16.5 & B31.1 & B31.3, API RP553 & 598 ) Size range from ½” thru 8” in ANSI class 150 & 300#, S/S & C/S materials of construction. This now allows simple replacement of traditional globe style control valves with the more accurate control slide gate technology.

VANEC is a leader in Industrial Silencers, Pulsation Control & Catalyst systems design and manufacturing and also joins RM Headlee product line offering. Vanec excels in solutions to lower noise from engines, compressors, vents, blow-downs- meeting Db requirements to specification. Lowering vibration from pulsation rotating equipment and lowering emissions caused by combustion, to environmentally acceptable levels are areas in VANEC’s wheel house.

Application Guidelines

As you know RM Headlee specializes as a knowledgeable & dependable Valve Automation Center (VAC).

One of the key areas is fully understanding correct sizing practices of actuators. The double edged sword is if you over-size an actuator you run the risk of destroying the valve along with being high in price. Under-sizing the actuator must be avoided as well for fear of not being able to cycle the valve and in the end costing you a fortune with warranty issues (not to mention the customer being very upset!)

RM Headlee follows the following guidelines on every RFQ:

*Obtain valve manufacturer torque requirement for application (i.e. media, temperature, maximum pressure, cycle frequency).

*Know the valve MAST (Max Allowable Stem Torque) The torque value not to exceed for concern of damaging the stem.

*SF (Safety Factor) expressed in %. We typically apply a 30% SF to most applications.

Application is the single most important aspect of our jobs at RM Headlee and we think we perform this well.

Technically Speaking (The Val-matic Series 9000 Tilted Disc Check Valve)

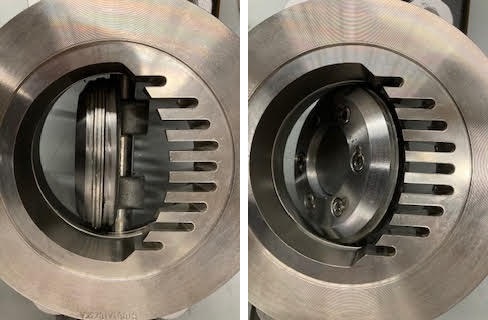

VAL-MATIC has your solution for pump discharge check valves. Introducing the Valmatic Series 9000 Tilted Disc Check Valve.

Intro:

Non-Slam closure using a short disc stroke of 40 degrees & energy savings compared to traditional check valves. This claim was achieved with a confirmed Cv of 140%.

Description:

Low head loss, AL bronze tapered metal seats are durable & corrosion resistant, upper & lower dash pot options to snub the disk cycle speed and action.

Function:

Violent disk cycling is avoided, reverse flow prevented achieving minimal to zero back flow due to the quick sensitivity of the disk.

Pressure/Flow Loss:

Example- On a 30” size valve at 26,500gpm ( 12ft/sec ) with a Cv of 42,000 a tilted disc has 6 times less head loss than a silent check

Surge Control

Surge is dangerous and complicated to correct / avoid. The goal is not letting the surge begin especially in non-compressible fluids.

Did You Know? (Meet the “Shark Tooth”)

Control valve technology has taken leaps and bounds from the traditional globe style styles. Yeary Controls based out of Chicago has brought to market several years ago a product called the SHARK-TOOTH element and when combined with a Zwick triple offset (TO) butterfly valve has some incredible performance characteristics.

Traditional globe style control valves fall short with minimum flows or trying to control at the lower end of sizing parameters. They tend to hunt always trying to hold downstream requirements and either uncapable to achieve this or end up wearing out the actuator. These valves also at best have seat leakage classification of 2-3-4.

The SHARK-TOOTH is mounted directly to the Zwick TO flange and incorporates a machined S/S dished teeth element such to allow the butterfly disc to cycle within very close physical tolerance of each other.

This allows a very accurate control range through the entire quarter turn action of the valve. The second benefit is Zwick TO valves are zero leakage when fully closed, this is unheard of for control valves.

The final benefit of the Zwick design is smooth steady movement of the disk when first coming out of the seat. This has to do with not wedging the metal seat into the valve body for sealing. Zwick stores the torsion kinetic energy into their shaft to close the disk making for a non-popping out of the seat reality.

The Cv & equal percent range of this Shark-Tooth package is comparable to Globe style control valves and requires simple quarter turn actuation over linear styles. Markets that have used this control package are: Natural Gas, Steam, HP Water, Air Separation or any process inside the pressure and temperature envelope and ratings.

If you have interest in Ideal Inherent equal % flow curve, Cavitation control / prevention & 6-15 dba aerodynamic noise reduction then consider the SHARK-TOOTH and contact RM Headlee.

Final Comments

Hang onto your hats. We have seen several instances of orders significantly delayed by supply chain issues. Whatever the reasons (and I understand there are many) the fact remains that goods made far away that must logistically go through ports, on ocean vessels, trucks & finally delivered to end destinations face all kinds of hurdles.

Missing promised ship dates is not the only problem. We are seeing almost every manufacturer we represent institute price increases. Quotes that normally mention 30 day validity are changing to 5-10 days or worse like saying price shall become firm at time of order.

RM Headlee will always work hard to convey full transparency when ship dates and price adjustments occur. We will not wait telling our clients when bad news happens. Knowing things change upfront without delay although not pleasant allows contingency plans so a crane or welders are not standing around with nothing to do but cost the project more.

The other way to skin the cat is RM Headlee investing in more inventory. We are moving forward on this concept to eliminate problems for our customers.

As we approach the Holidays we are Thankful for our health, families, first responders, our customers and the RM Headlee team. We wish all who visit this site a wonderful 2022.

Gary Beckett, VP Business Development