“Heads Up”

Quarterly Newsletter: February 2023

Jump To

Latest News | Application Guidelines | Technically Speaking | Final Comments

Latest News

If you read my last Newsletter of 2022, I made mention of Old Man Winter approaching. My goodness, did it ever approach!

Buffalo, NY was hit with 7 feet of Lake effect snow on November 18th and if that wasn’t enough a second storm on December 23rd dumped another 6 feet but this time with 70 MPH winds sustained for 48 hours.

There was tragedy, but many heroic stories as well. Our hats off to first responders, snow removal, Police force, ect… As Lake Erie cools down and eventually freezes over, we hope big snow events are less.

RM Headlee is very busy starting 2023. We thank all our customers and industrial equipment manufacturers we represent for a solid 2022. RM Headlee is growing. We are well supported by all our principals, and we care about the equipment we sell and that it works once installed meeting the specifications and application requested by our customers.

RM Headlee has greatly increased our Orchard Park, NY valve and actuator inventory to better protect lead times for our customers. Supply chain issues are still a problem. One of Aumas electric actuator competitors is at 52 weeks delivery as one example.

Wishing all of you a healthy & prosperous 2023 and we thank you for your time when our salesman contact you for opportunities. We hope to earn your trust and business and become a key supplier too you!

– Gary Beckett, V.P. of Sales

Application Guidelines

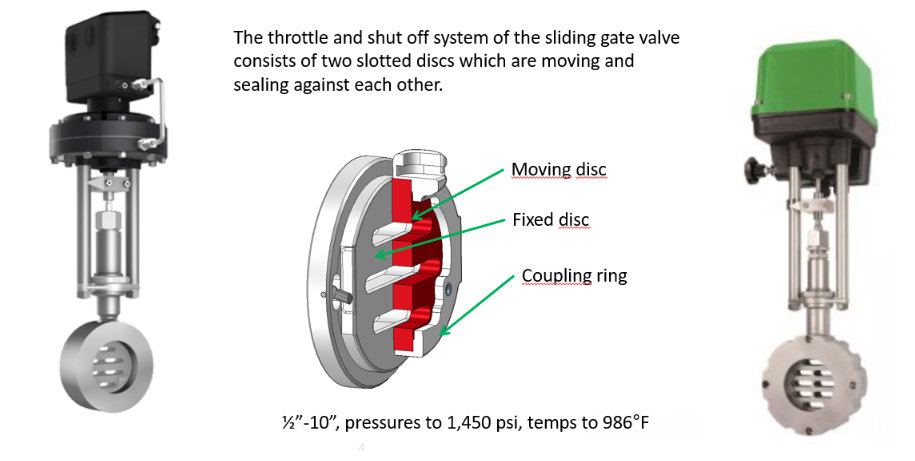

RM Headlee Represents Schubert & Salzer for Sliding Gate Control Valves. They offer market leading technology for steam control. There is a fixed disc and a moving disc as shown in the image below:

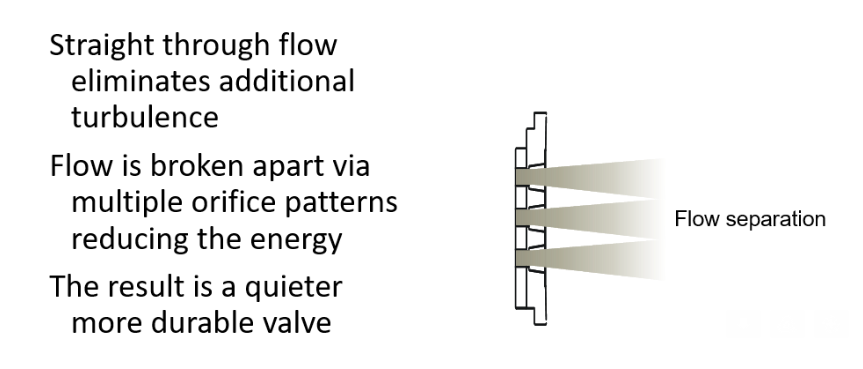

- Straight through flow

- Ability to make a “fail closed” valve into “fail open” by flipping the moving disc

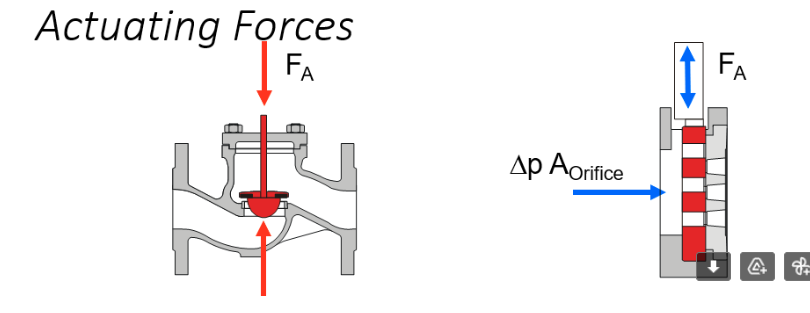

- Actuator not fighting the fluctuation of process pressures or flows when operating.

This allows the sliding gate to offer extremely accurate steam temperatures for the process. This application helps the food industry create the same quality food for allof its customers. It helps tire manufactures make the same consistent tire day in and day out.

Quiet Operation

Low Energy Consumption

A customer called the other day to tell me that anticipated steam pressure at this section of the plant was supposed to be 60PSI… but ended up being 100 PSI. The control valve was now way over-sized for this application.

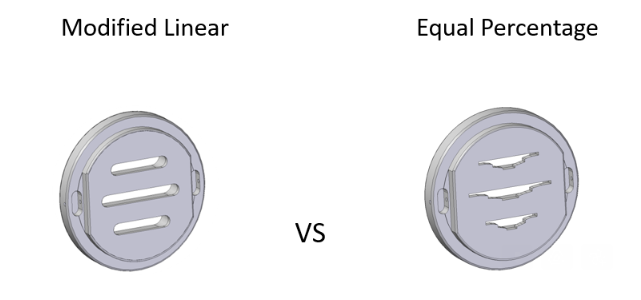

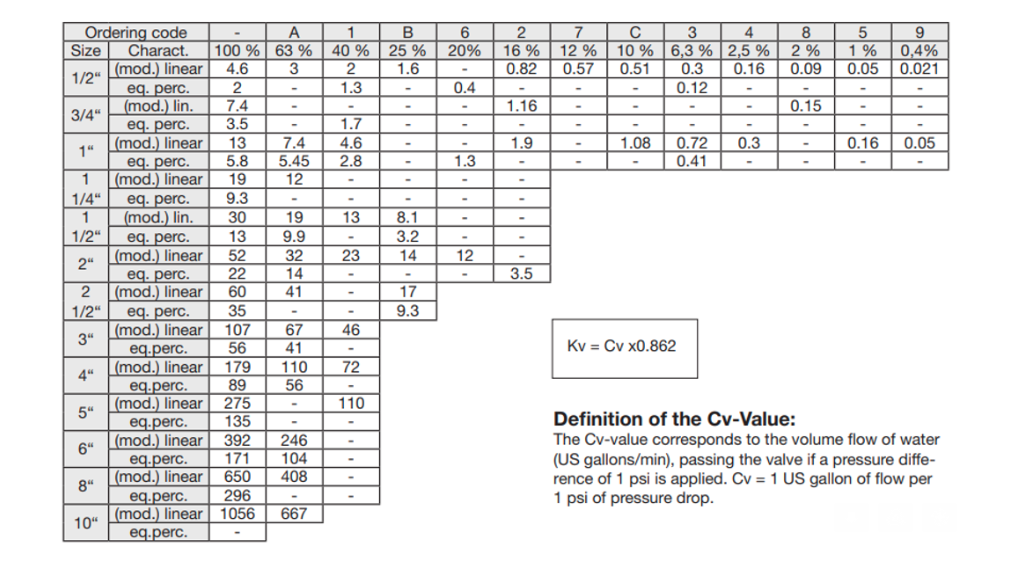

One of the many advantages of choosing R.M. Headlee as the supplier of your sliding Gate valves is our offering of multiple Cv trim options by simply changing out the moving disc. For this customer, we were able to keep the piping size all the same and simply insert a reduced trim so the actuator is properly sized. The customer was relieved they did not have to cut the piping and install a complete new size control valve… talk about a “cost saving solution!”

We also proposed another option to calibrate the actuator to change the full open position to 50% travel; that way, it was no longer over-sized. This is only a “soft stop” and the customer wanted to guarantee the smaller Cv by putting the correct disc in the valve. With the customers Fail Safe Electric Actuator it uses super capacitors to fail closed on loss of signal or power.

RM Headlee’s engineers have the ability to size and select the appropriate valve for any of your process needs. Don’t hesitate to contact us!

Selectable Cv Values

Technically Speaking

The City of Rochester’s drinking water comes from the Cobbs Hill Reservoir located near the center of the city. It is fed thru a 36” main by gravity from the Hemlock Water Plant 30 miles away. The iconic fountain, in the middle of the reservoir (built in 1908), utilized a gate valve in the fountain structure and operated by the hydraulic power system located in the gate house, to create the back pressure necessary for the fountain to work.

The gate valve and hydraulic system served a long service life of over 100 years. When it became inoperable, the city searched for options to keep the fountain in service.

The requirements were:

- Vendor needed to size a valve to create the required backpressure during both the summer and winter months.

- The new solution required the valve and actuator to be capable of total submergence downstream of the fountain. Since the fountain structure was well over 100 years old, the city was going to abandon the gate valve in place and in the open position.

- Valve actuator needed to be throttled from the gate house.

Most valve styles would cavitate due to the significantly different flow rates between summer and winter. After eliminating the easy options like butterfly, another gate, ball, or plug valves, R.M. Headlee zeroed in on a pinch valve.

Using Red Valve’s sizing program, the optimum size was determined to be a Type A Pinch Valve with a 36” x 20” cone sleeve. To save considerable cost, R.M. Headlee proposed using (2) 36” x 24” ductile iron concentric reducers, (1) upstream & (1) downstream of the valve, with the 24” Type A pinch valve with a 24” x 20” cone sleeve. Utilizing the configuration, reducer and cone sleeve, provided the flow coefficient to handle the low winter flow rates as well as the much higher summer flow rates.

In addition to the cone sleeve option, the Type A provided an additional benefit of ease of actuation. Actuation of the Type A, the PINCHING action, is accomplished by air or hydraulic pressure placed on the elastomeric sleeve. The valve body acts as a built-in actuator, eliminating costly and hard to submerge pneumatic, hydraulic or electric actuators.

Modulating the air/hydraulic pressure within the annular space between the body and sleeve will open, throttle or close the valve. RM Headlee proposed using city water, that was readily available, to actuate the valve. This eliminated the need for a costly compressor, hydraulic power unit or electrical controls.

R.M. Headlee’s solution was accepted, installed and to this day still proving the spectacular view of the 115 year old fountain that is enjoyed by hundreds of daily walkers, bikers and joggers!

Final Comments

I live in a 35-year-old ranch home south of Buffalo, NY. I bought it “as is,” in 50% finished construction, because I would not have been able to afford it if it were finished. With two high energy young boys I decided early on to finish the basement, so they could destroy that part of the house, keeping my blood pressure down!

Recently, I took a hard look at the condition of this 30 plus year old cave and realized it needed attention. The basement is an open room about 1000 square feet and I decided a good place to start was painting the ceiling. I drove to the Sherwin Williams paint store, waited my turn and the salesman behind the counter asked “how can I help you?”

After explaining the many details of: room size, wanting to put two coats on, and the need to hide a few marks and seal in a little mold from sump pump moisture issues, he came up with suggesting a 5 gallon pail over single gallon sizes. Now it’s been a while since I purchased good paint and I fell off my chair on the cost. It was explained to me that buying a 5 gallon pail would save me $50.00 but I was still lying on the floor.

I don’t normally do this, but I further asked “What else could you do to help me get this cost lower?”

He mentioned if I added rollers, a handle extension, tape and a few brushes he would sweeten the deal. It was a win / win for all.

When selling or buying industrial valves and actuator packages, think outside the box to maximize value! If a project has 10EA identical valve packages and this equipment is critical to keep a plant up and running, push further and ask for a spare back-up or suggested spare parts up front.

Lastly, the better salesman – after working hard on application, and offering best equipment solution at a fair price- should always ask for the order.

Good Hunting,

Gary S. Beckett

Gary Beckett, Vice President of Business Development